Home » Design Technology

DFMEA is a structured engineering methodology to identify potential failures in design and mitigate risks before production.

Module 1: FMEA Fundamentals

Module 2: Failure Mode Identification Techniques

Module 3: Severity, Occurrence, Detection Ratings

Module 4: RPN Calculation

Module 5: Criticality & Risk Prioritization

Module 6: Recommended Actions

Module 7: DFMEA Templates & Case Studies

Module 8: Best Practices in Automotive & Aerospace

PFMEA ensures manufacturing processes are robust, safe, and optimized for quality and efficiency.

Module 1: Introduction to PFMEA

Module 2: Process Flow Diagram (PFD)

Module 3: Failure Mode Analysis

Module 4: Severity, Occurrence, Detection

Module 5: Control Plan Development

Module 6: Corrective Actions

Module 7: PFMEA Documentation & Auditing

Module 8: Industry Case Studies

Hardware-in-the-loop (HIL), Software-in-the-loop (SIL), and Model-in-the-loop (MIL) simulations validate embedded systems before real hardware deployment.

Module 1: Control Systems Overview

Module 2: Introduction to MIL, SIL, and HIL

Module 3: Simulink-Based Controller Modeling

Module 4: Real-Time Simulation Tools (dSPACE, NI)

Module 5: Code Generation using Embedded Coder

Module 6: Plant Modeling

Module 7: Test Automation & Validation

Module 8: Real-World Case Studies (Automotive/Robotics)

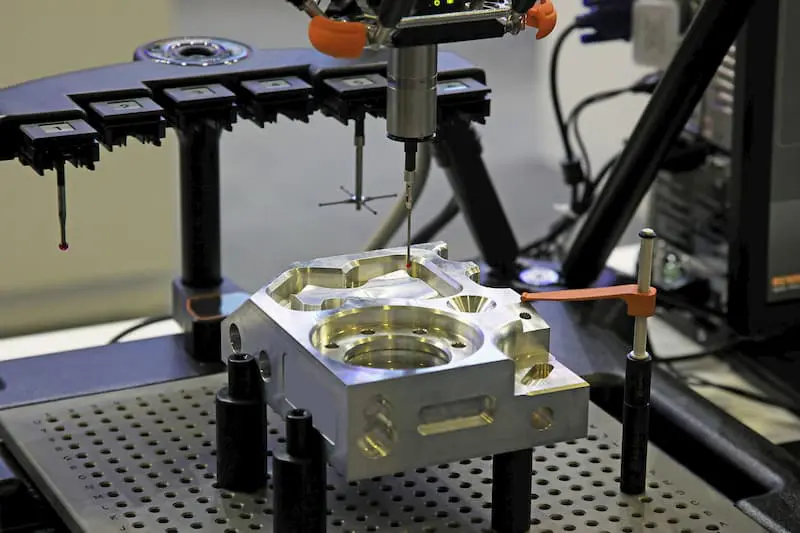

GD&T standardizes how engineers define tolerances, shapes, and allowable variations on engineering drawings to ensure manufacturability.

Module 1: Introduction to ASME Y14.5

Module 2: Datum Systems

Module 3: Form, Orientation, Location, and Runout Symbols

Module 4: Tolerance Zones

Module 5: Feature Control Frames

Module 6: Basic Dimensions

Module 7: Inspection Methods

Module 8: Practical Case Studies

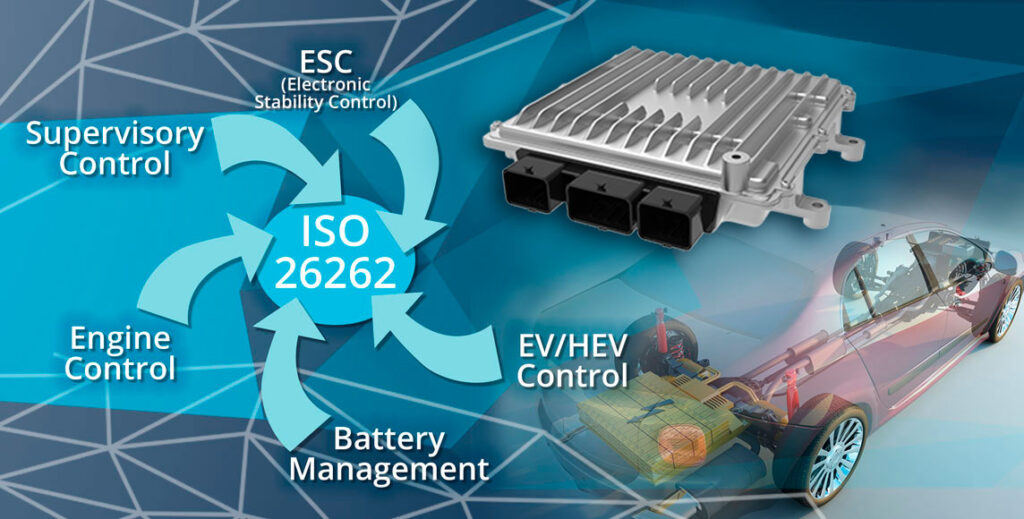

Functional Safety ensures electronic systems operate safely even during faults, primarily focused on automotive electronics under ISO 26262.

Module 1: Functional Safety Fundamentals

Module 2: ISO 26262 Framework

Module 3: HARA (Hazard Analysis & Risk Assessment)

Module 4: ASIL Levels & Safety Goals

Module 5: Safety Lifecycle & V-Model

Module 6: Safety Mechanisms & Architecture

Module 7: Software & Hardware Safety

Module 8: Safety Case Development

Module 9: Industry Projects (EV/ADAS)

we are formally known as Headwaters Training Consultants Pvt. Ltd. PROPUPIL empowers growth through tailored solutions that boost leadership, performance, and strategic alignment.

© Copyright 2025. All Rights Reserved By PROPUPIL Learning Consultants. Designed by Digju.com